Robotic Automation Solutions Design In Pune By Parc Robotics

As industries evolve, the demand for enhanced efficiency, productivity, and precision grows. In this context, robotic automation has emerged as a game-changing solution across various sectors. Pune, renowned for its burgeoning technology landscape, is home to several innovative companies, among which Parc Robotics stands out.

Specializing in robotic automation solutions, Parc Robotics leverages cutting-edge technologies to design systems that transform businesses' manufacturing and operational processes. This article explores Parc Robotics' offerings, its significance in Pune’s industrial ecosystem, and the future of robotic automation in the region.

The Rise of Robotic Automation

Robotic automation encompasses the use of robotics technology to automate repetitive tasks, thereby reducing human intervention. With advancements in artificial intelligence, machine learning, and the Internet of Things (IoT), robotic systems are no longer confined to just manufacturing.

Today, they are capable of complex tasks across various domains such as healthcare, logistics, agriculture, and more. This surge has been particularly beneficial in Pune, a hub for information technology, manufacturing, and engineering services, resulting in a growing interest in automation solutions.

Overview of Parc Robotics

Founded to revolutionize the automation landscape, Parc Robotics has positioned itself as a leader in robotic solutions in Pune. The company’s ideology centers around creating systems that enhance operational efficiency and are user-friendly, scalable, and customizable to meet clients' specific needs.

Services Offered

Parc Robotics provides a wide array of services that cater to different industrial needs:

- Robotics Process Automation (RPA): Automating processes to reduce costs and improve accuracy.

- Custom Robot Design: Tailored robotic systems designed to meet particular operational requirements.

- Integration Services: Seamless integration of robotic systems into existing workflows without causing disruptions.

- Maintenance and Support: Providing ongoing maintenance services to ensure operational continuity.

- Consultation: Offering expert advice on how businesses can leverage robotics for maximum impact.

Industries Served

Parc Robotics serves a diverse range of industries, including but not limited to:

- Manufacturing: Streamlining assembly lines and quality control processes.

- Logistics: Enhancing warehousing operations through automated retrieval and sorting systems.

- Healthcare: Assisting in surgeries, patient care, and inventory management of medical supplies.

- Food and Beverage: Automating packaging, sorting, and quality inspection processes.

Advantages of Robotic Automation

Implementing robotic solutions from Parc Robotics carries numerous benefits:

- Increased Efficiency: Robotic systems can operate continuously without fatigue, significantly boosting productivity.

- Cost Reduction: Automation reduces labor costs, minimizes errors, and decreases waste, leading to substantial savings.

- Improved Quality: Robots deliver consistent and precise operations, enhancing the overall quality of products or services.

- Safety Enhancements: By automating dangerous or repetitive tasks, companies can reduce workplace accidents and ensure employee safety.

Case Studies of Successful Implementations

To illustrate the impact of robotic automation, let’s take a look at a few successful case studies from Parc Robotics:

Case Study: Enhancing Production Efficiency and Quality with Custom Robotic Assembly Line

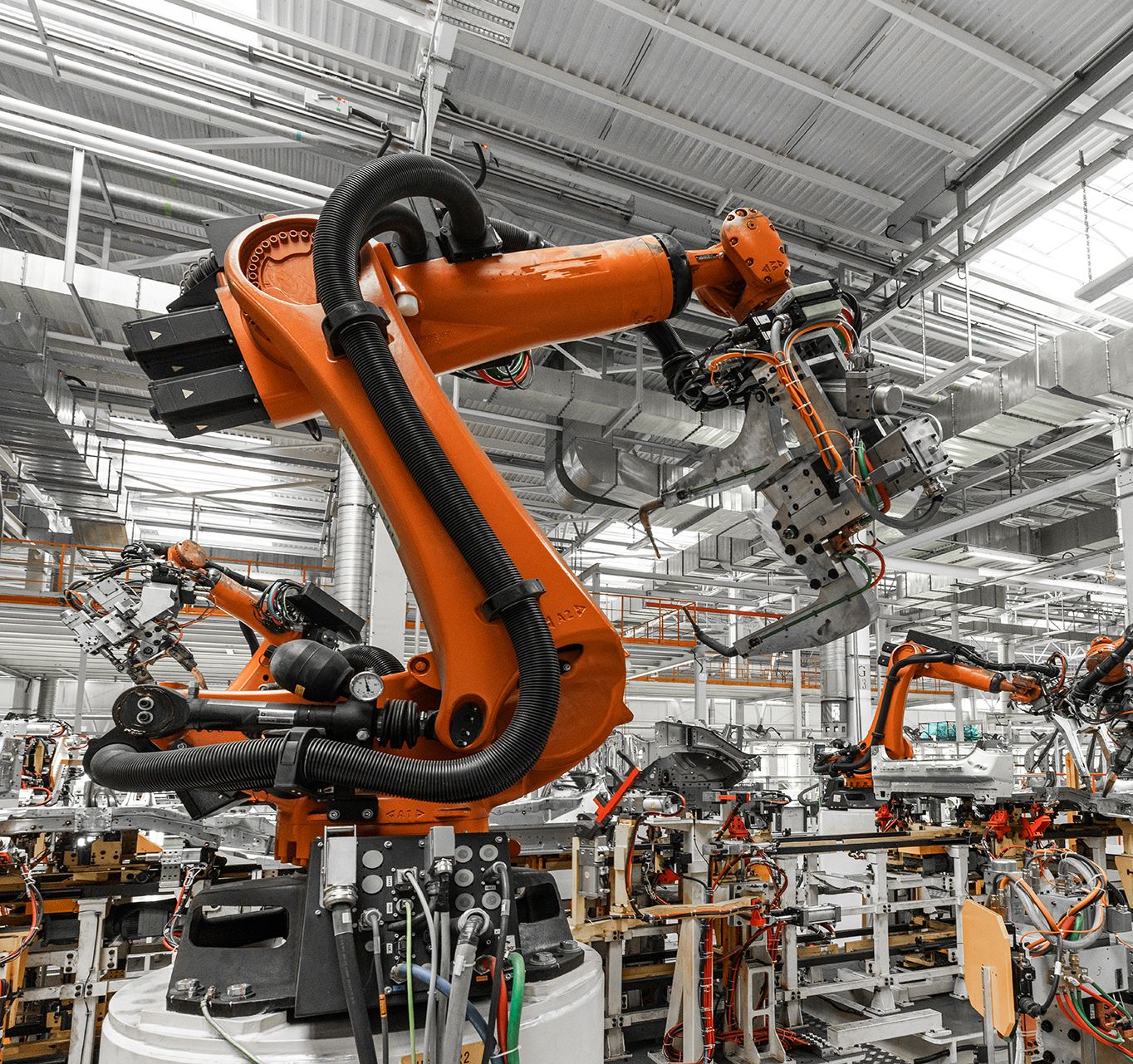

In an automotive manufacturing plant, Parc Robotics implemented a custom robotic assembly line that automated various stages of vehicle assembly. By integrating robotic arms capable of performing welding, painting, and assembly tasks, the plant achieved a 30% increase in production efficiency. Moreover, the quality of the assembled vehicles improved, leading to a significant reduction in rework and scrap rates.

Case Study: Optimizing E-Commerce Order Fulfillment with Robotic Sorting and Retrieval System

In the fast-paced world of e-commerce, timely order fulfillment is crucial. Parc Robotics designed a robotic sorting and retrieval system for a major e-commerce warehouse in Pune. The system utilized automated guided vehicles (AGVs) to transport goods across the warehouse, drastically reducing pick-and-pack times by 50% and improving overall throughput. This implementation not only increased operational efficiency but also enhanced customer satisfaction through timely deliveries.

Suggested Content: Canvas Manufacturing Automation: The Essential Guide for Manufacturers

The Future of Robotic Automation in Pune

As Pune continues to grow as a technology hub, the future of robotic automation looks promising. Factors driving this growth include:

- Increased Demand for Automation: As businesses look to reduce operational costs and improve productivity, the trend towards automation will likely accelerate.

- Government Initiatives: Supportive government policies and initiatives aimed at promoting smart manufacturing and Industry 4.0 are expected to foster innovation.

- Enhanced R&D: Ongoing research and development in robotics, AI, and IoT are likely to yield more advanced and efficient robotic solutions.

- Skill Development: As more companies adopt robotic solutions, the focus on training and skill development will ensure a workforce that can handle sophisticated technologies.

Challenges in Robotic Automation Adoption

While the prospects for robotic automation are bright, several challenges need addressing:

- High Initial Investment: The upfront costs associated with implementing robotic systems can be significant, dissuading some businesses from adopting them.

- Integration Issues: Seamlessly integrating robotic solutions into existing workflows can be complex and may require substantial changes to business processes.

- Workforce Transition: As robots take over more tasks, companies must manage the transition for their workforce to minimize job displacement.

Conclusion

Parc Robotics is at the forefront of the robotic automation revolution in Pune, offering innovative solutions that enhance efficiency, reduce costs, and improve quality across various industries. As businesses increasingly recognize the value of automation, the demand for robotic solutions will continue to grow.

With ongoing advancements in technology and increasing government support, Pune is well-positioned to become a leading hub for robotics and automation, making a significant impact on both the local and global industrial landscape.

The future is bright for industries willing to embrace the potential of robotic automation, and Parc Robotics will undoubtedly play a crucial role in shaping that future.

.png)

Comments

Post a Comment